Metal is an indispensable material in modern times. It can be used in almost every field. It needs to be processed if it is to be transformed into products of various shapes and functions.

To work a metal you need to heat it, because heat is the easiest way to change its shape, but the traditional way of heating it is to burn fuel to create a high temperature environment and then heat the metal in that environment.But it takes a long time to do this, and there is now a way of heating metals very quickly, which is induction heating.

What is induction heating

Induction heating, also known as electromagnetic induction heating, is a method used to bond, heat treat, weld, soften metals or other conductive materials. For many modern manufacturing processes, induction heating improves the speed and efficiency of heating.Induction heating has been used in manufacturing since the 1920s, and during World War II the technology developed rapidly to meet wartime demands for rapid heating of metal parts.This method of heating is unique. The usual method is to heat metal parts directly over a fire. Induction heating uses a different method of heating parts by circulating an electric current to create "induced" heat on the parts.

How induction heating works

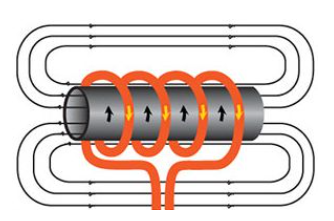

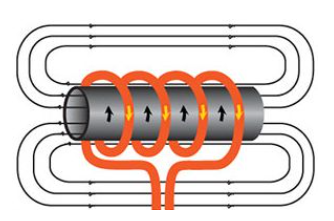

How does induction heating actually work?Induction heating is mainly used to heat the principle of magnetic field, the heating system is mainly induction coil, power supply and metal workpiece need to be heated.

Induction heating power supply is to convert the AC power supply to a higher frequency AC power, which will be transmitted to the induction coil, and the electromagnetic field will be generated in the coil.Due to heat the metal workpiece is also conductor, coils produced by induction coil can directly penetrate into the coil in the magnetic induction line metal artifacts, and form the current loop, and the resistance of the metal is lesser, coupled with high current, when the high current of the magnetic induction line through the metal artifacts, will let the electrons within the metal is very active, collide with each other,Heat is generated by friction, which causes the metal to heat itself quickly

Features of induction heating

1.Ensure product quality

Induction heating does not need direct contact with open fire, can ensure the quality of all products, only need to set and calibrate the temperature, each product will not appear heating uneven and heating temperature deviation, can ensure the heating quality of each product.

2.Improve production efficiency

Because the heating speed is very fast, it can maximize the production efficiency, the equipment can make the workpiece in a few seconds to produce more than 800~1000 degrees of heat, can be said to be an instant start, without preheating or cooling cycle.

3. Prolong fixture life

Induction heating can heat the metal to a specific location and quickly transfer the heat to an area of the part without heating any of the surrounding parts, which extends the life of the fixture and machinery.

4.More environmentally friendly and safer

Induction heating systems do not burn conventional fossil fuels and heating is a clean, pollution-free process that will help protect the environment.

5.Reduce energy consumption

Induction heating converts 90 percent of the energy into useful heat, compared to 45 percent for conventional furnaces, and since the induction process does not require preheating or cooling cycles, standby heat losses are minimized.